Quality Control

Quality Control

Technology Advantage

Choose a good supplier, Product Quality is the first important factor to consider. Quality evaluations include fitment, material quality, paint quality, sticker accuracy, and overall durability.

Technology Advantage

Choose a good supplier, Product Quality is the first important factor to consider. Quality evaluations include fitment, material quality, paint quality, sticker accuracy, and overall durability.

01

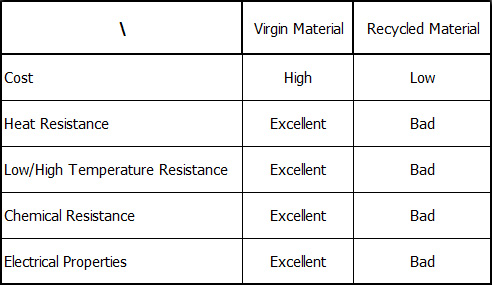

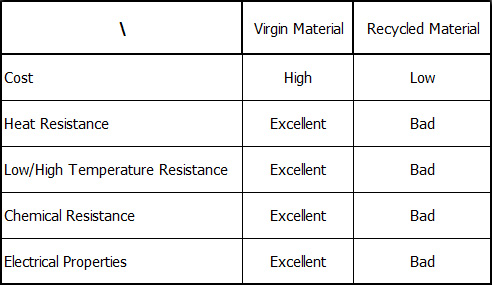

Raw Material

Over the years, we have insisted on using ABS virgin materials and refused to use recycled materials to ensure product quality.

01

Raw Material

Over the years, we have insisted on using ABS virgin materials and refused to use recycled materials to ensure product quality.

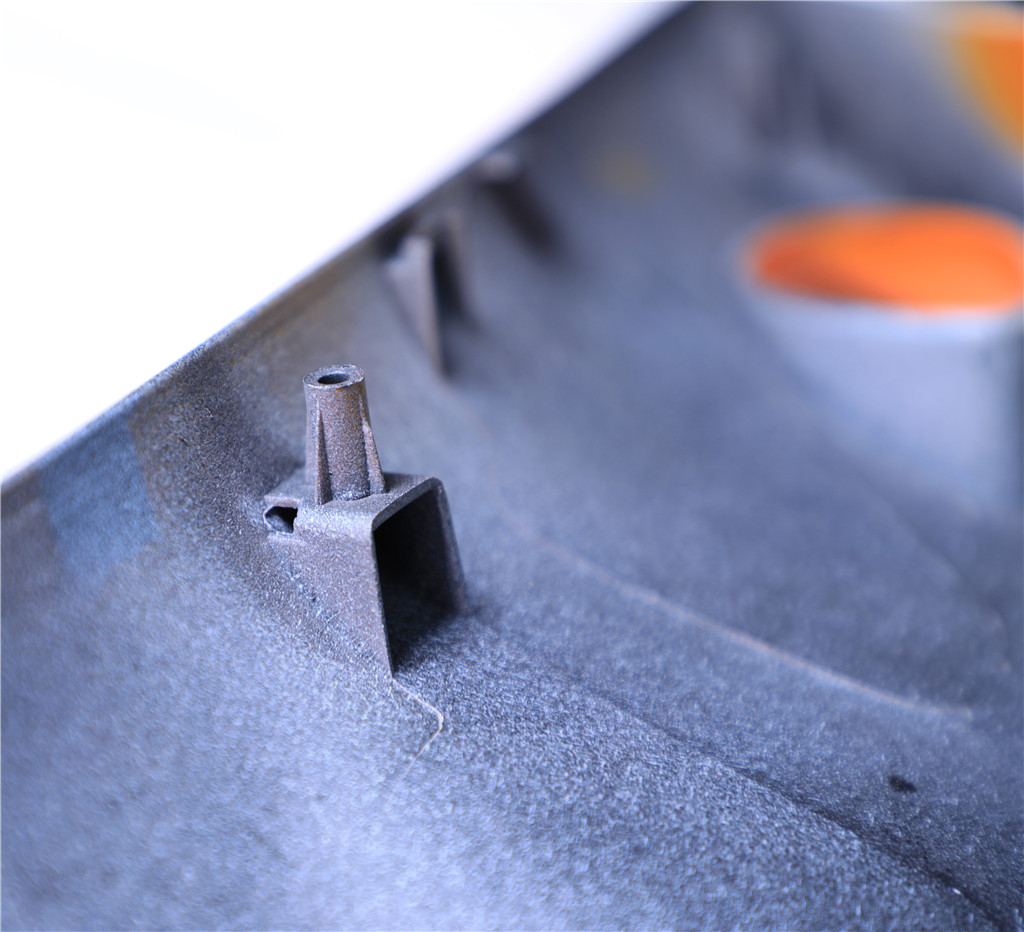

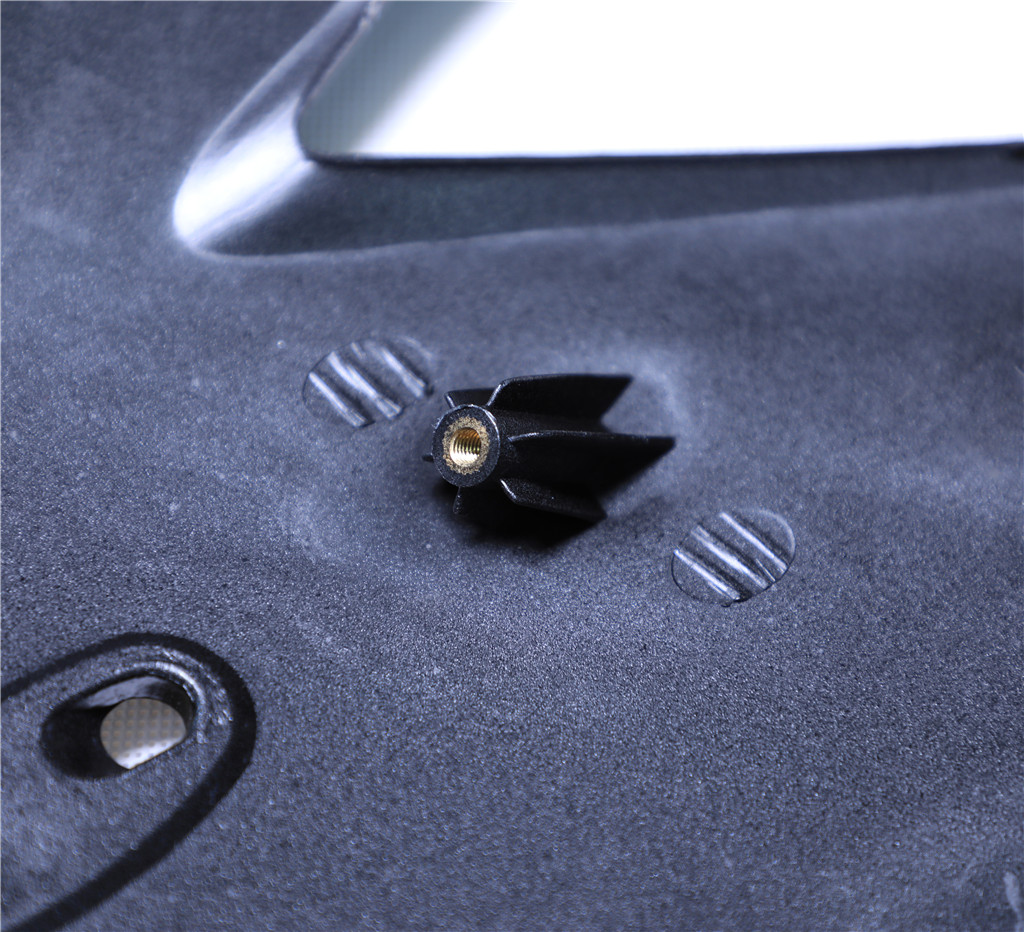

02

Injection Mold

We use injection mold only, which is made with OEM bodywork, installation accuracy almost reaches 100%

02

Injection Mold

We use injection mold only, which is made with OEM bodywork, installation accuracy almost reaches 100%

03

Paint Quality

Primer :

Make base painting is a very necessary process, it can be used to improve the adhesion of topcoat, increase the fullness of topcoat, provide alkali resistance and anti-corrosion function. Besides, it can ensure the uniform absorption of topcoat and make the best effect of the paint system. In order to cut cost, many painting factories do not make the primer, lead to poor adhesion and easy peeling of topcoat.

03

Paint Quality

Primer :

Make base painting is a very necessary process, it can be used to improve the adhesion of topcoat, increase the fullness of topcoat, provide alkali resistance and anti-corrosion function. Besides, it can ensure the uniform absorption of topcoat and make the best effect of the paint system. In order to cut cost, many painting factories do not make the primer, lead to poor adhesion and easy peeling of topcoat.

Painting Job :

Angle and running speed of the spray gun is very important to painting quality. The spray gun should be kept running at right angle and parallel to the fairing. The moving speed of the spray gun is usually adjusted between 30 and 60 cm/s, and it’s required to be constant. If the spray gun is inclined or with variable speed, it will not get uniform paint film, and easily have stripes and spots issue; When spray gun runs too slow (less than 30 cm/s), it will easily produce flow hanging. When the uniformity of coating thickness is required to be high, cross spraying method should be adopted to ensure the quality of paint.

Painting Job :

Angle and running speed of the spray gun is very important to painting quality. The spray gun should be kept running at right angle and parallel to the fairing. The moving speed of the spray gun is usually adjusted between 30 and 60 cm/s, and it’s required to be constant. If the spray gun is inclined or with variable speed, it will not get uniform paint film, and easily have stripes and spots issue; When spray gun runs too slow (less than 30 cm/s), it will easily produce flow hanging. When the uniformity of coating thickness is required to be high, cross spraying method should be adopted to ensure the quality of paint.

Clear Coat :

It is one of the most important processes to a beautiful paint job, it plays a protective role. However the main painting problem “cracking” usually appear at this step. Clear coat is applied to the surface of the fairing and cured by ultraviolet radiation. The curing time mainly depends on the wavelength of UV light. The higher the output intensity of UV light, the faster the curing speed. Time control is more suitable in about 20 seconds. Improper control of UV will lead to excessive temperature, thus cracking paint. At our workshop, from molding to paint, the entire manufacturing process is overseen by our own skilled professionals and operators. Especially in controlling the accuracy of UV wavelength and time, Top Fairingkit are so skilled that there has never been any cracking problem.

Clear Coat :

It is one of the most important processes to a beautiful paint job, it plays a protective role. However the main painting problem “cracking” usually appear at this step. Clear coat is applied to the surface of the fairing and cured by ultraviolet radiation. The curing time mainly depends on the wavelength of UV light. The higher the output intensity of UV light, the faster the curing speed. Time control is more suitable in about 20 seconds. Improper control of UV will lead to excessive temperature, thus cracking paint. At our workshop, from molding to paint, the entire manufacturing process is overseen by our own skilled professionals and operators. Especially in controlling the accuracy of UV wavelength and time, Top Fairingkit are so skilled that there has never been any cracking problem.

04

Inspection

This is an indispensable process and plays an important role in controlling quality and eliminating mistakes. Before delivery, we will arrange three quality inspections. The sales manager will check the first one, the third-party quality inspection company will pass the second one, and the production director who has more than 10 years’ experience in the company will pass the third one. Every single part will be inspected to ensure it’s perfect. The inspection includes inspecting color, decal, model no. and so on.

04

Inspection

This is an indispensable process and plays an important role in controlling quality and eliminating mistakes. Before delivery, we will arrange three quality inspections. The sales manager will check the first one, the third-party quality inspection company will pass the second one, and the production director who has more than 10 years’ experience in the company will pass the third one. Every single part will be inspected to ensure it’s perfect. The inspection includes inspecting color, decal, model no. and so on.

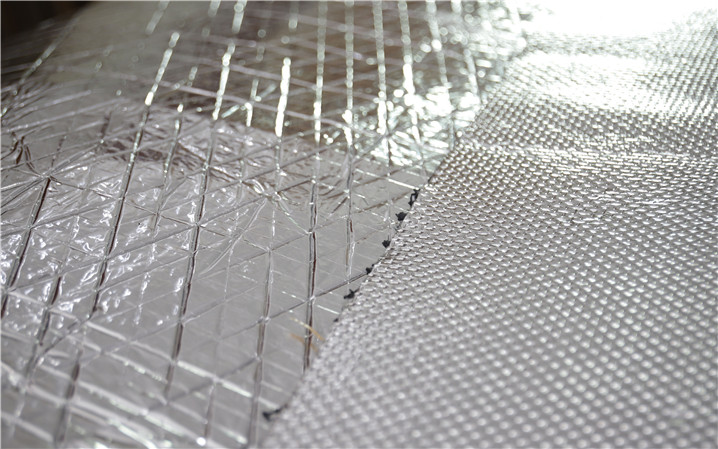

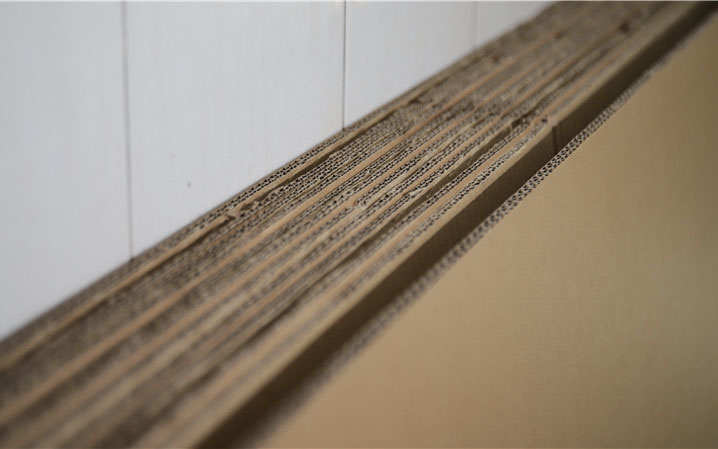

05

Packaging

Two layers of pearl cotton pack fairing inside and outside, Besides we only use the high quality seven layers of corrugated cartons. We guarantee that the damage rate is lower than 2.43%.

05

Packaging

Two layers of pearl cotton pack fairing inside and outside, Besides we only use the high quality seven layers of corrugated cartons. We guarantee that the damage rate is lower than 2.43%.

Wear Resistance Test