9 ways to cut off $15 per fairing kit to factory (you never know before)

What is business negotiation: negotiation is a process of combining divergent positions into a joint agreement under a decision rule of unanimity. In fact, business negotiation can be well summarized in one sentence: the purpose of maximizing the interests of the conversation is business negotiation.

Businessmen pursue and maximize profits are the essence of business. Maybe you’ve read too many business negotiation books and learned a lot about negotiation strategies. The book will tell you in business negotiations , you should be careful, be honest, be flexibility, be confident. These doctrines are shit in my eyes. After reading numerous articles, you find that you still have no way to start when you finally face the supplier. In fact, the book’s negotiation skills simply do not play a substantive role in the reality negotiation, because it’s divorced from reality. In order to win the business negotiation, the most important thing is to have a thorough understanding of the national conditions, the operation of the local market and even the operation of every production process in the factory. Otherwise, you will find that the negotiations between you and the factory are deadlocked and unable to move forward.

To bargain, you must understand the cost structure of the product first. But factory will never tell you and you can never get it through Google search. As a foreign purchaser, you are eager to cooperate with Chinese suppliers, but you don’t know anything about Chinese internal market. How will you negotiate effectively with factories?

As the leading manufacturer of motorcycle fairing in China, topfairingkit.com has been insisting on honest management and standardized production. The openness of production cost and process make the cooperative customers feel at ease. This article will give you a thorough understanding of the cost structure of China’s motorcycle fairing industry, so that you can do the fairing business in China unimpeded. It is probably the only article you’ve ever read that really analyses the cost of a set of motorcycle fairing. Take the opportunity to read as soon as possible, and we will probably release this article only at a limited time.

Now let’s take a look at the cost structure of the fairing in China. The big secrets of the industry you want to know are all here: (settled in US dollars: RMB – 1:6.5)

1. Raw materials

Choose original or recycle ABS?

Prices of different materials is much different. Want to be successful in negotiation, first you must learn how to identify them and know what’s the difference of their performance.

1) The way of identification:

* Look at the color.

Look at the back of the fairing (no spray paint). White is original ABS, gray is the recycle ABS.

* listen to the voice.

The unpainted fairing of recycle material will sound more crisp, while the original material will sound dull.

2) Performance differences

* Flexibility

The performance difference between original ABS and recycle ABS is the flexibility. Recycle ABS is brittle and easy to crack. In fact, most of the fairing are transported by air which requires high flexibility. Believed that many purchasers have encountered the problem that motorcycle fairing is damaged during transportation. This has a great deal to do with the raw materials. At the same time if you encounter the supplier who pay no attention to packaging and don’t take responsibility for damage parts, you will even lose money on the fairing business.

* Spray paint adhesion

The spray adhesion of recycle material is not as good as that of original. The same quality of paint, sprayed on the original and recycle material effect will be much different. The week adhesion will lead to the paint peel off easily. Many customers ever asked me why the label peel off when I use the motorcycle fairing for a period of time. This is related to the raw material. Recycle ABS has poor adhesion and slight bulging of painting, which results in sticker warping.

Recycle material is about 10% cheaper than original material. According to the average price ¥300 of unpainted fairing, a set of recycle ABS fairing is about $ 3.07 cheaper. But if you don’t know how to identify or don’t pay attention to the raw materials used by the manufacturer, you’re likely to buy recycle ABS at the original price.

2. Painting Job

Common paint VS UV light paint, cost difference is in equipment. A set of equipment is about $107,000.00. Once invested, it takes 5 to 8 years to earn back the cost. Usually, the price of UV light paint is about $3.07 higher than that of ordinary spray paint.

As a purchaser, first of all, confirm the fairing you buy is what kind of paint. If it’s ordinary paint, it can at least reduce $3.07 a fairing set. Of course, you have to accept the quality of ordinary paint. If you want to learn how to identify common paint and UV light paint, please refer to the quality control page of our company’s website: https://www.topfairingkit.com/quality-control/

Summary: As a purchaser, it is not necessary to purchase UV light paint for every market. Our suggestion is to purchase according to the market demand. In some markets such as Africa and Southeast Asia, consumers are pursuing price advantages and layout design. But the durability of the fairing kit is not so important for them. In this case, it is most suitable to purchase ordinary painted fairing. In some markets such as Germany and Japan, consumers pursue high quality and are insensitive on price. So UV spray-painted fairing are more suitable for them. But in some markets such as the United States, where demand is diversified. Purchasers need to buy according to the group of consumers they are targeting.

In addition, besides purchased according to the market demand, you must also consider the mode of transportation. UV light paint has many advantages, but some manufacturers do not control temperature and time very well during the process lead to the paint crack. There is a certain incentive for cracking paint, which is a long time of high temperature. Usually, the fairing kit travels long distances in a container for 1-2 months. The internal temperature can reach up to 57 degrees. In this case, if the UV light paint quality is not good enough, cracking will occur. If your ABS fairings need shipping by sea, be sure to select a quality assured UV paint manufacturer. If the UV painting technology is not up to standard, then ordinary paint is a better choice. According to our years of experience, common spray paint rarely have crack problem.

Of course, if you have high quality requirements and have to ship fairing kit by sea, topfairingkit.com manufacturer will be your best choice. In the past years, the crack incidence rate of our UV light painted fairing is 0%.

3. Wages of workers

1) Painter

How many years’ experience the painter had? Is he native of Jieshi town? Generally, the salary of young painter from other places is about ¥4000, while the salary of local experienced painter can be as high as ¥7000 or even more. According to the production capacity of 500 sets per month, the local painter’s cost of one set of fairing is $0.93 higher.

Painting is the key process to determine ABS fairing kit quality. And the quality of painting is determined by the skill of painter. The base painting is not good will directly affect the clear coat. No good UV light equipment can work well if the painter is not professional.

Jieshi Town is a major motorcycles fairing production town, has the most professional painter in China. Many local painters have been working on aftermarket fairing since the 1990s when the local people began to produce the first set of fairing. A 40-year-old painter usually has 20 years of work experience. Rich experience makes them perfect in quality control. However, with the expansion of business, the local rare painters are in short supply. Many factories began to recruit young and inexperienced painters to replace them outside. But because Jieshi Town is remote and the painting material is not good for health, the younger generation of painter can not stick to work for a long time. So that the mobility of the painter is high.

Therefore, it is better to know the technical team of the factory first when negotiating with the factory. It helps to control the quality of products well and reduce costs. Chinese Spring Festival is the most headache festival for Chinese factories. As we know the peak period of the fairing business is after the Spring Festival, but the painters from other place usually delay to go back to work in order to claim higher treatment. It has a big influence on the delivery time of order. Maybe your order is often delayed by the factory in February – March, and you were told that because there are too many orders to fulfill. In fact, it’s because the workers are not in place. An experienced painter is usually a local who will stick to his post for a long time. They have professional responsibility and will not strike without reason.

2) Sales team

Cost of a good sales team in the factory is high, but can greatly reduce the cost of customer communication. In China, the sales income is usually consist of salary and commission. For the fairing sales, it is about ¥3000 salary plus 1% of sales volume. That is to say, if the production capacity is 500 sets of monthly you need to pay to the salesman $0.92 for every set of fairing. While according to the average unit price $250 of the fairing kit, commission of $2.5 is required for each set. So your cost on the salesman for each motorcycle fairing is 0.92+2.5=$3.42.

The role of the factory’s own sales team is enormous. If the factory does not have a professional sales team, then it will be difficult for you to cooperate with the factory. The communication between you and your factory will be not easy and you have to takes much more time on it.

4. Supplier type

If you do not cooperate directly with the factory, you can also choose the following three ways to purchase the fairing kit:

- Through sourcing agent.

- Through trade company.

- By hiring local translators to purchase from factories

But the cost of purchasing through the above three channels is much higher than purchasing directly from factories.

No matter your supplier is a sourcing agent or a trade company specializing in motorcycle accessories, they will charge a fee. Sourcing agents charge for purchasing services while trade companies earn the difference. Generally speaking, the sourcing agent’s service fee is about 5% of the purchasing amount. While the gross profit of the trade company is at least 15% or more. Based on the average unit price of $250, the sourcing company charges at least $12.5 per set. While the trade company needs to add at least $37.5 as a profit. It’s $9.08 and $34.08 higher than the cost of factory salesmen.

In addition to cost factors, for the other advantages and disadvantages of these two companies please refer to our hot articles: https://www.topfairingkit.com/teach-you-how-to-hunt-for-a-good-motorcycle-fairing-supplier-in-China/.

You might say that hiring local translators is probably the most cost-effective way. At present, the translation fee on the market is about $150 a day. But generally such translators do not know about the product and production process. They are just a microphone function similar to Google translation. Some of the professional knowledge involved is difficult for them to translate accurately. It’s difficult for you to understand the production process and the product characteristics. It’s not good for the negotiation.

5. Fairing kit decals

1) Commone Decal

The decals is easily overlooked in negotiations. In fact, a set of ordinary decals has a great impact on the cost of fairing kit. The price of one set decals is about $3.07. At present, many purchasers like to order the fairing kit that with pure color. For two main reasons: to avoid unnecessary brand disputes and easier customs clearance. If all your orders are in pure color, you can let the factory subtract the cost. If you don’t ask for it, most factories won’t take the initiative to lower your price. Even if you mention about the cost, the factory maybe will tell you that the cost with decal or not is almost the same. But the actual price is quite different. Many customers don’t know the secrets of the industry, so they have to pay more. After reading this article, you will no longer be fooled by factories.

2) Chrome Decal

Another kind of label is called chrome decal. This kind of label is optional because it’s attached on the clear coat and can be removed by yourself. Normally chrome decal’s cost is not included in the quotation so customers have to pay extra. The price is about $6.15 a pair. So if your suppliers ask you to pay extra for this, don’t worry they are not deceiving you. Cost of Chrome label is high due to the high cost of the label mould. But the decal is so stereoscopic that looks very beautiful when stick on the fairing kit.

6. Local freight

More than 70% of the motorcycle fairings are transported by air express. But from the factory to the airport, there is also a section of domestic transportation. There are two modes of domestic transport:

1) Domestic Express: Cross-city Express, the express fee for a set of motorcycle fairing is about $7.69.

2) By truck, the average transportation cost of a fairing kit is about $4.61.

There is a difference of $3.08 between the above two transportations.

Generally speaking, the fairing kit will be expressed to the airport if the factory is with small sales volume. Big factories with big sales volume, they would love to rent a truck to transport fairing kit to the airport. Except saving cost, transported by truck can reduces the risk of damage effectively. Because each carton is loaded and unloaded by the factory itself. This ensures that every link is under the control of the factory, and that every fairing kit is carefully handled.

7. The workshop

The workshop of factory is rented or renovation of self-owned housing?

The largest production base of fairing kit is Jieshi Town. Many of the factory buildings in this town are renovated by their own houses and some are rented. Make sure what kind of the your manufacturer workshop is. Generally the annual rental cost is at least ¥50,000. The average cost of a set of fairing kit is $1.5, based on the conventional capacity of 6,000 units a year.

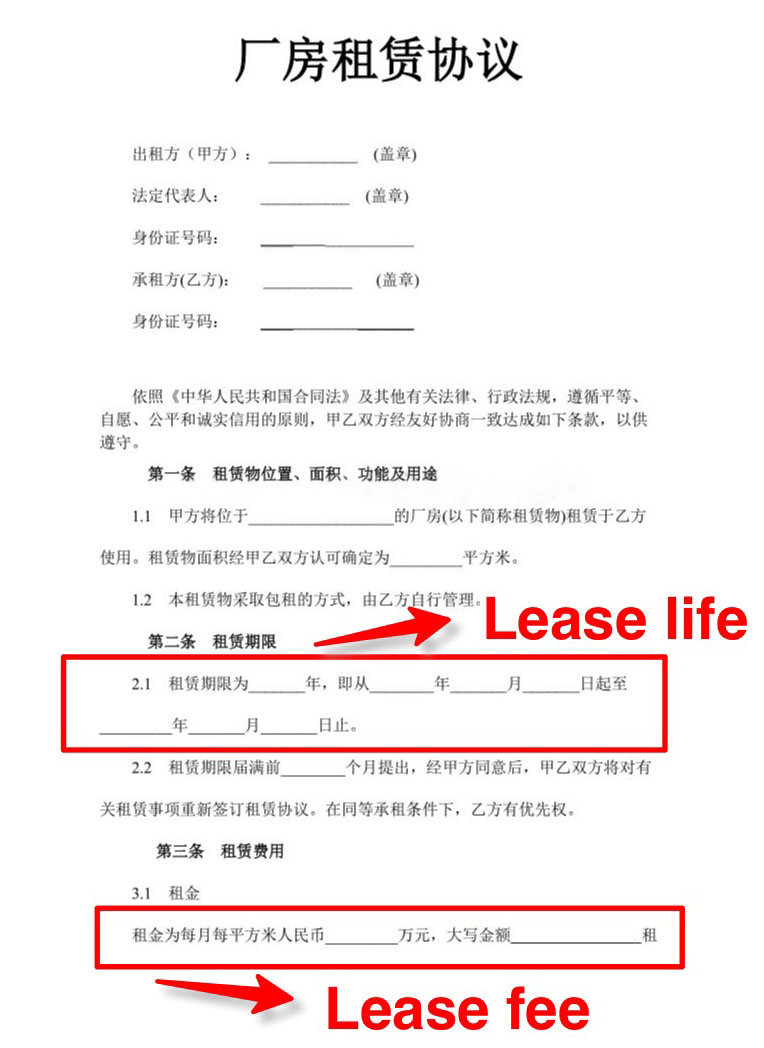

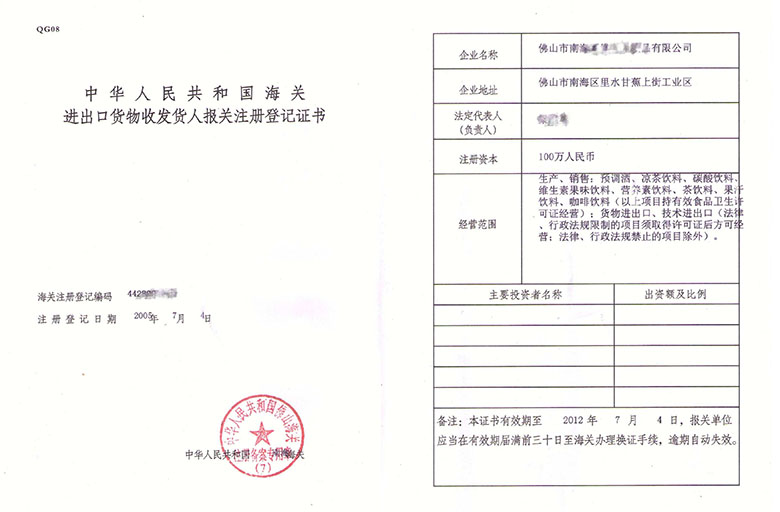

So how to judge the attributes of the workshop? You can ask the factory to show you the contract. The leased workshop will have a formal lease contract. All you need to know from the contract includes: rent, lease life, whether the lease contract is registered to government; Whether the leased workshop is leased at one hand? All of these will as shown as below:

And the factory building which renovated by own houses, usually has the property ownership certificate, as shown in the figure below. So it’s easy to judge them.

Maybe you’re worried that the factory will be reluctant to show the lease contract. In fact, a regular factory with sincerity to cooperate with you, they will try their best to show you a variety of documents to let customers have confidence to cooperate with them.

So what’s the difference between the two plants?

- Workshop renovated by self-owned buildings:

High stability and low cost. However, such factories usually do not have business licenses and are not regulated by government departments.

- Leased plant:

High liquidity and high cost. But because the lease contract is registered on file, the factory usually has a formal operating licensing right and business license. They are regulated by the industrial and commercial departments and pay taxes regularly.

The difference of factories with or without business license, please see the TIP 8 for a detailed analysis.

8. Business license

Whether factories have business licenses can tell whether they pay taxes. Some manufacturers’ workshops renovated by their own houses. Most of them do not have business licenses. Therefore, it is not regulated by any industry and Commerce Department and never pays taxes. According to the current tax and fee regulations in China, a factory has to pay VAT, enterprise income tax, stamp tax, land use tax, education fee attachments of urban construction tax and other additional taxes. Value-added tax alone is 17%. In addition to other taxes requires at least 25% tax. Tax evasion reduced the operating costs of factories. But this kind of factory is not supervised by any department. There will be serious irregularities in the production process. Like arbitrary discharge of harmful substances causes environmental pollution, arrears of workers’ wages and some serious hidden dangers to production safety. If the supplier you are working with is a factory that do not pay taxes. The price of each set of fairing kit can be cut down at least $15.

However, their production capacity may be unstable due to various factors. Such as being sealed up by EPA due to serious pollution problems; Wage arrears leading to frequent workers’ strikes; No supervision by fire department so prone to fire and other security risks. All of these factors may lead to your order can’t to be completed on time, or even your deposit will drift.

For purchasers, the best supplier should be a factory with its own workshop and have business license. Such a factory has low cost and production is also more secure.

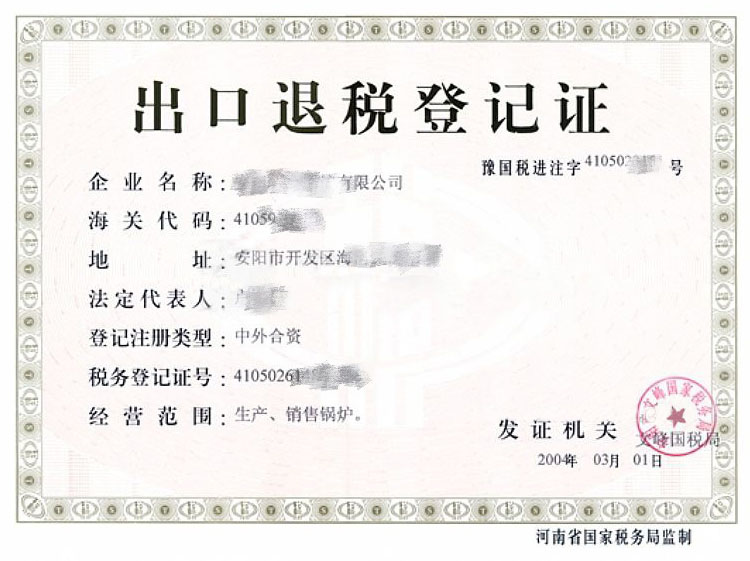

9. Tax rebate

The right to import and export mainly refers to the qualification of enterprises to carry out import and export business transactions.

It is a troublesome process to apply for the import and export rights of enterprises. Enterprises that apply for import and export need to be approved by the relevant departments such as the Municipal Commerce Bureau, the Municipal/District Customs, the Electronic Port Inspection and Quarantine Bureau and the Foreign Exchange Administration at the same time. Only after obtaining various certificates approved by the above departments, can the enterprises indicate that they have the right to import and export by themselves.

So at present, most of China’s motorcycle fairing factories do not have the right to import and export. The reasons are:

- The process of applying for import and export rights is troublesome

- Most of the fairing kit are exported by air express, no need the import and export rights.

- More importantly, the application for import and export rights must pay taxes to the Chinese government first.

For the purchasers mainly by air express, the imported goods do not involve the right of import and export. But if your order is mainly shipped by sea, whether the supplier has import and export rights will have a great impact. Because the Chinese government refunds taxes on various export products to encourage exports. Motorcycle accessories exports have a tax rebate of up to 14%, which means that the cost of the factory is greatly reduced, which can be your bargaining chip with the factory.

So how to inquire whether the company has the right to import and export?

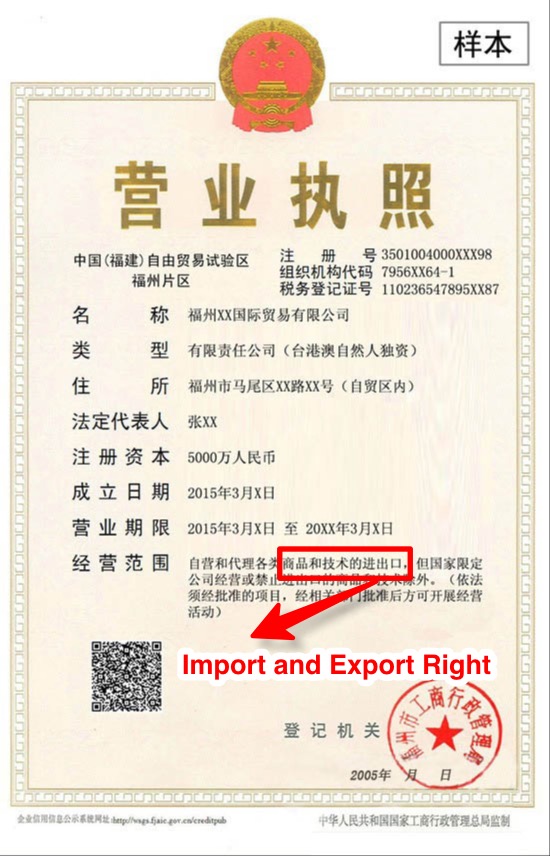

1) We can see if there is any in its business scope (import and export of goods, import and export of technology). All these words indicate that it has the right to operate import and export. As shown in the following figure:

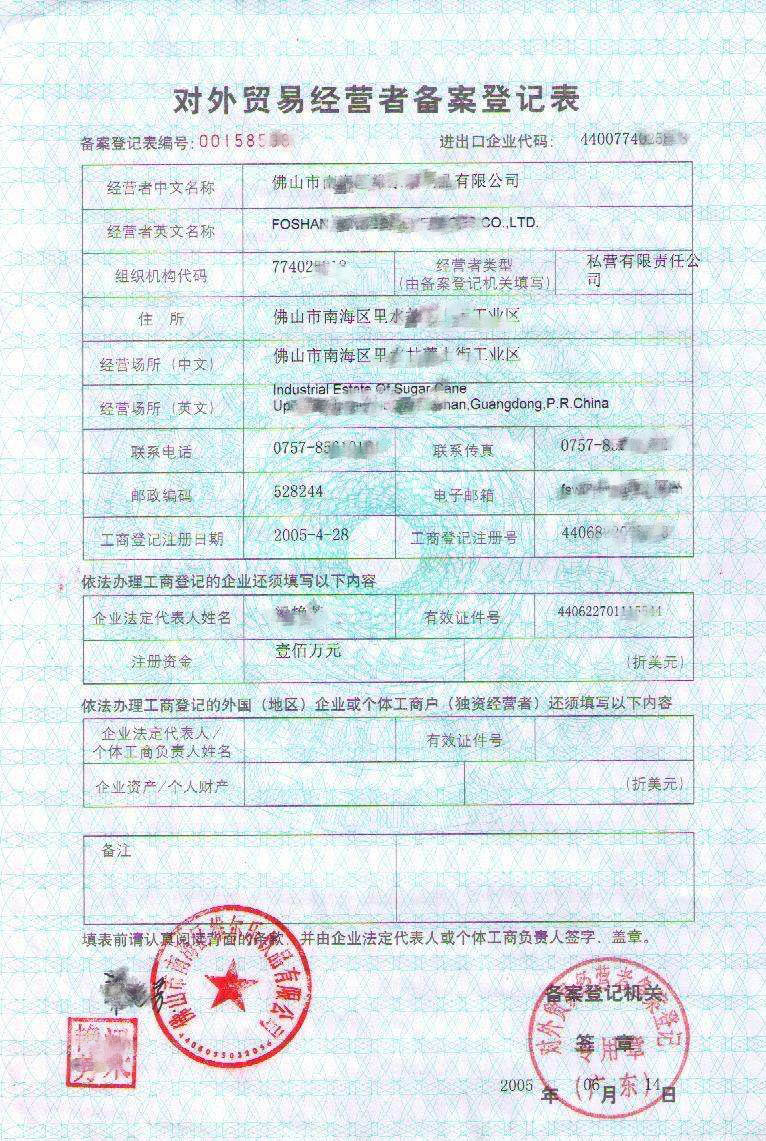

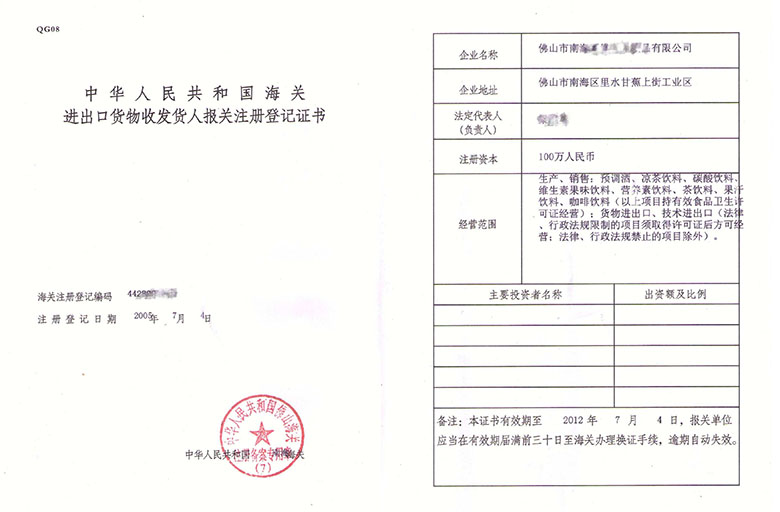

2) It is also possible to determine in detail by looking at the following documents of the company:

* Registration forms for foreign trade operators (issued by commercial departments);

* Certificate of Registration of Self-handling Customs Declaration Unit (Customs);

* Registration Certificate of Tax Refund for Export Enterprises (Tax Bureau);

* Check VAT invoices

But if a company wants to get an export rebate, it must have VAT invoice. That is to say it must pay 17% value-added tax to the Chinese government first. For factories that do not have business licenses and do not pay taxes, getting the tax rebates is even need to pay for higher cost.

So if you are going to bargain with the factory on the tax rebate, first of all, you need to find out whether the factory has paid taxes normally. If so, a tax rebate can bring you a substantial reduction in the price.

From the above analysis, we can see that some of the costs need to be paid, and some can be omitted through your research and learning. If you ever read this article before negotiation, you will save of at least $9.08 in selecting suitable suppliers, $3.07 in decal cost and $3.08 in transportation. The total cost savings were $9.08+3.07+3.08=$15.23. Other TIP fees, such as the type of raw material and painting, the salary of the painter, whether to pay taxes and get tax rebate. All of these tips can help you save at least $50 per fairing kit. To help you avoid spending high costs on mismatched services.

In fact, the key to really save costs is to find a excellent supplier. A good supplier can help you avoid detours and develop your business in the long run. Although some of the costs will be higher for cooperation with regular factories, production and quality is guaranteed. It’s conducive to the long-term interests of both sides.

Follow us to learn the knowledge of the aftermarket fairing industry, you will benefit a lot. Read this article you could save at least $50 for a set of fairing kit. If you have any questions or want to discuss more with us about the motorcycle fairing and accessories cost structure, please leave a message to us. Your motorcycle fairing expert is always here to help to push your business forward.

Leave A Comment